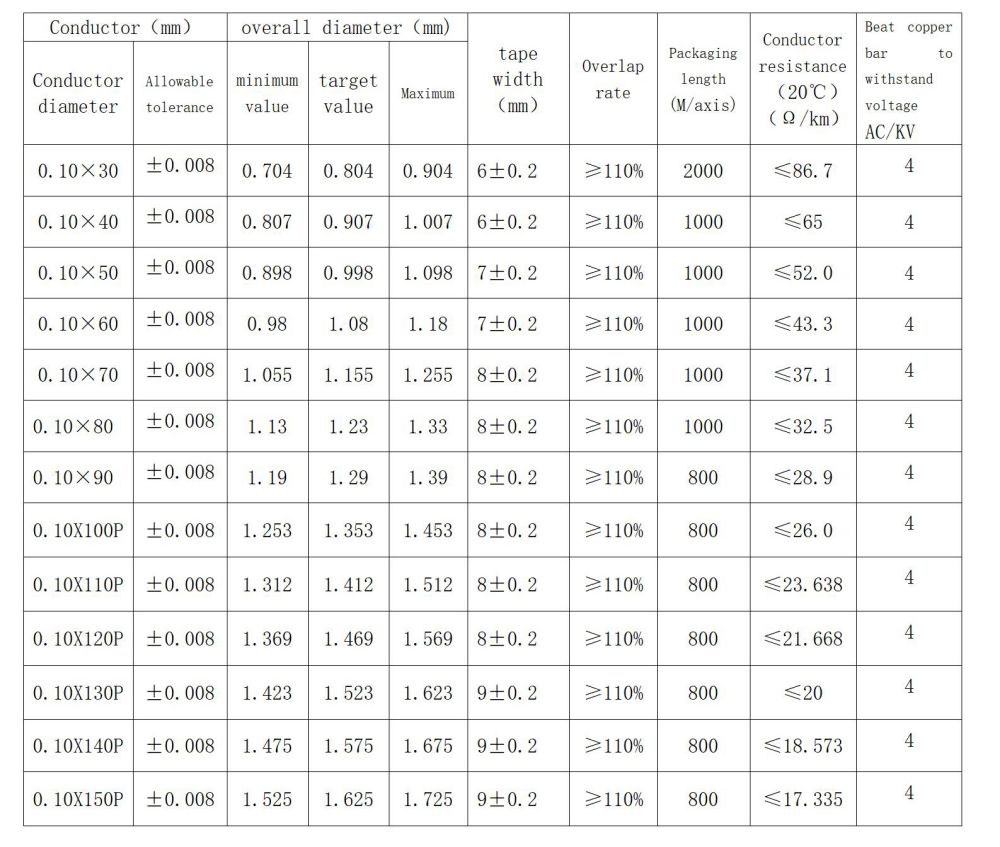

Process capability: High temperature Mylar tape film covered wire 0.25mm ~ 1.0mm (15 ~ 35M/min) 0.10mm * 7p~0.10mm * 300p (13~20M/min) Product characteristics: High temperature resistance, strong toughness, easy adhesion, and the dielectric strength also exceeds that of a single material Film coated wire, an electromagnetic wire coated with synthetic film or film of other materials as the insulating layer on the surface of the conductor or enamelled stranded wire according to a certain overlap rate. Our company's film coated wire has two internal structures, and different external films are used for different requirements, and different scenarios for the use of external films are also different 1. Four layers of insulated wire: PET+PTE+PA+PET tape (CT-280B/CT-285) 2. Four layers of insulated wire: ETFE+ETFE+ETFE+tape 3. High temperature insulated wire: polyurethane+PI tape (brown) Due to high temperature resistance and high insulation, it is widely used in the field of high-frequency transformers, high-power transformers, magnetic rings, such as medical equipment, inverters, high-frequency inductors and transformers, wireless chargers, etcProcess capability: Hot melt adhesive tape film cladding wire 0.25mm ~ 1.0mm (15 ~ 35M/min) 0.10mm * 7p~0.10mm * 300p (13~20M/min) Product characteristics: Compared with self-adhesive wire, it has higher flexibility and smaller outer diameter

Process capability: High temperature Mylar tape film covered wire 0.25mm ~ 1.0mm (15 ~ 35M/min) 0.10mm * 7p~0.10mm * 300p (13~20M/min) Product characteristics: High temperature resistance, strong toughness, easy adhesion, and the dielectric strength also exceeds that of a single material Film coated wire, an electromagnetic wire coated with synthetic film or film of other materials as the insulating layer on the surface of the conductor or enamelled stranded wire according to a certain overlap rate. Our company's film coated wire has two internal structures, and different external films are used for different requirements, and different scenarios for the use of external films are also different 1. Four layers of insulated wire: PET+PTE+PA+PET tape (CT-280B/CT-285) 2. Four layers of insulated wire: ETFE+ETFE+ETFE+tape 3. High temperature insulated wire: polyurethane+PI tape (brown) Due to high temperature resistance and high insulation, it is widely used in the field of high-frequency transformers, high-power transformers, magnetic rings, such as medical equipment, inverters, high-frequency inductors and transformers, wireless chargers, etcProcess capability: Hot melt adhesive tape film cladding wire 0.25mm ~ 1.0mm (15 ~ 35M/min) 0.10mm * 7p~0.10mm * 300p (13~20M/min) Product characteristics: Compared with self-adhesive wire, it has higher flexibility and smaller outer diameter